Asset labels identify equipment using a unique serial number or barcode. Asset tags are typically labels that have an adhesive backing. Common asset tag materials are anodized aluminum or laminated polyester. Common designs include the company logo and a border that provides contrast to the equipment. Barcodes are used on asset tags to speed data entry and to reduce field entry errors. The function of asset tags has changed – to accommodate ever smaller, more mobile and more valuable assets. As a result, asset tags have changed – to be more smaller, more tamper resistant and to become more closely integrated with asset tracking software. Asset tags have four basic functions:

• Track Equipment. Where’s my asset? Tags are used to track as they move from tool crib to construction site, from loading dock to lab or just from room to room. Asset tags must stay with the asset itself – over its lifetime. Use for check-in / check-out.

• Inventory Control. What assets do we own? Whether a school must comply with Title II funding rules or a business to tie down purchases to meet traceability requirements, asset tags are the critical link as you perform periodic audits of your asset list and calculate the value of the asset over it’s life cycle.

• Prevent Theft. Could you return the asset? Make it easy for anyone to return a valuable laptop or instrument to the proper owner. Prevent “accidental” misappropriation of your asset by another department.

• MRO Information. What maintenance needs to be done? Scanning a barcode can quickly bring the user to a data base of repair instructions or maintenance schedules.

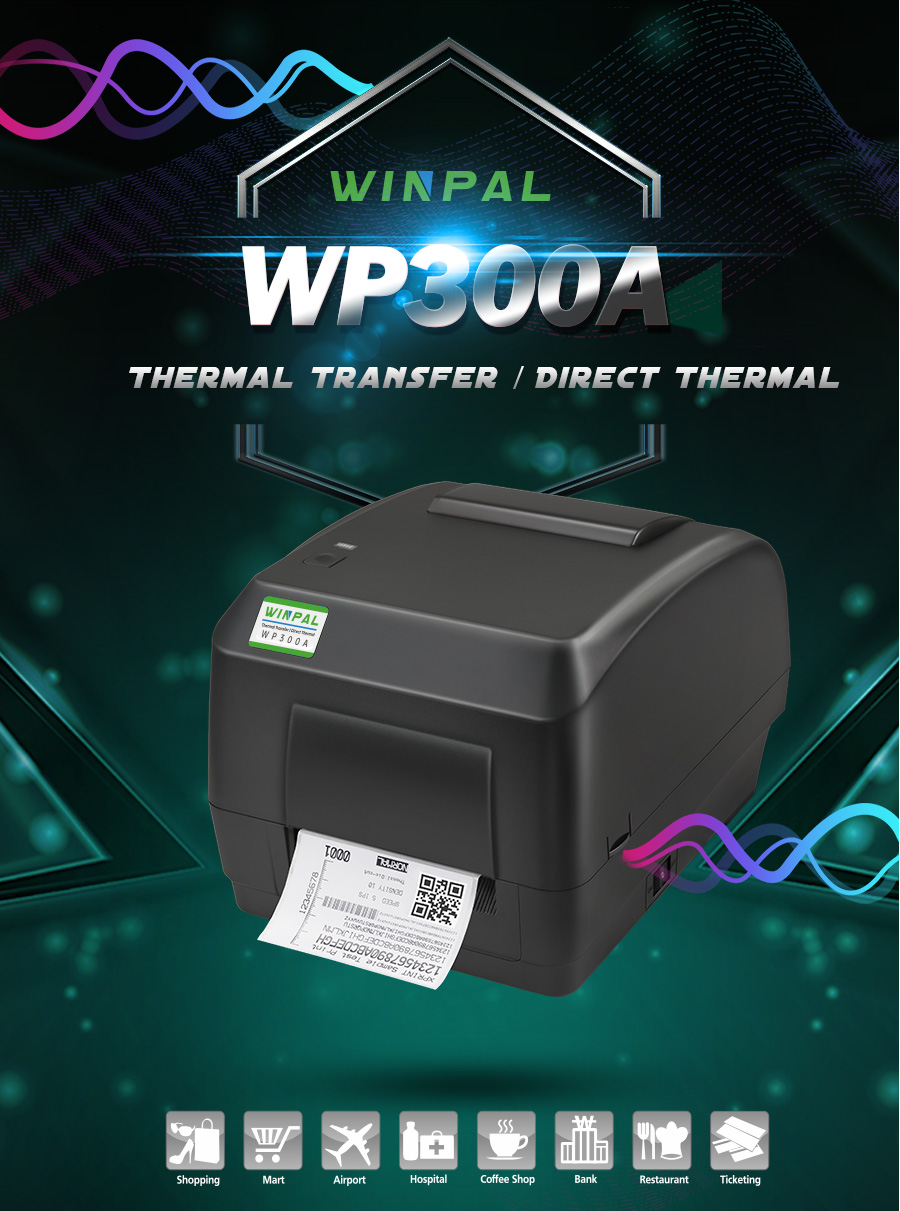

Winpal Printer has all types of Label Printers suited to various application & environments.

Please contact us (https://www.winprt.com/contact-us/)if you would like to more information or would want to place order.

Post time: Dec-03-2021