I believe we often encounter such a situation. When you go to a shopping mall or supermarket to buy something, you will see a small label on the product. The label is a black and white vertical line. When we go to the checkout, the salesperson uses a Scan this label on a product with a hand-held scanner, and the price you should pay for that product is instantly displayed.

The vertical line label mentioned here, the technical term is called bar code, its wide application makes its corresponding equipment rapidly popularized, and bar code printer as one of the important equipment for bar code application is widely used in manufacturing, logistics and other industries that need to be printed in the label industry.

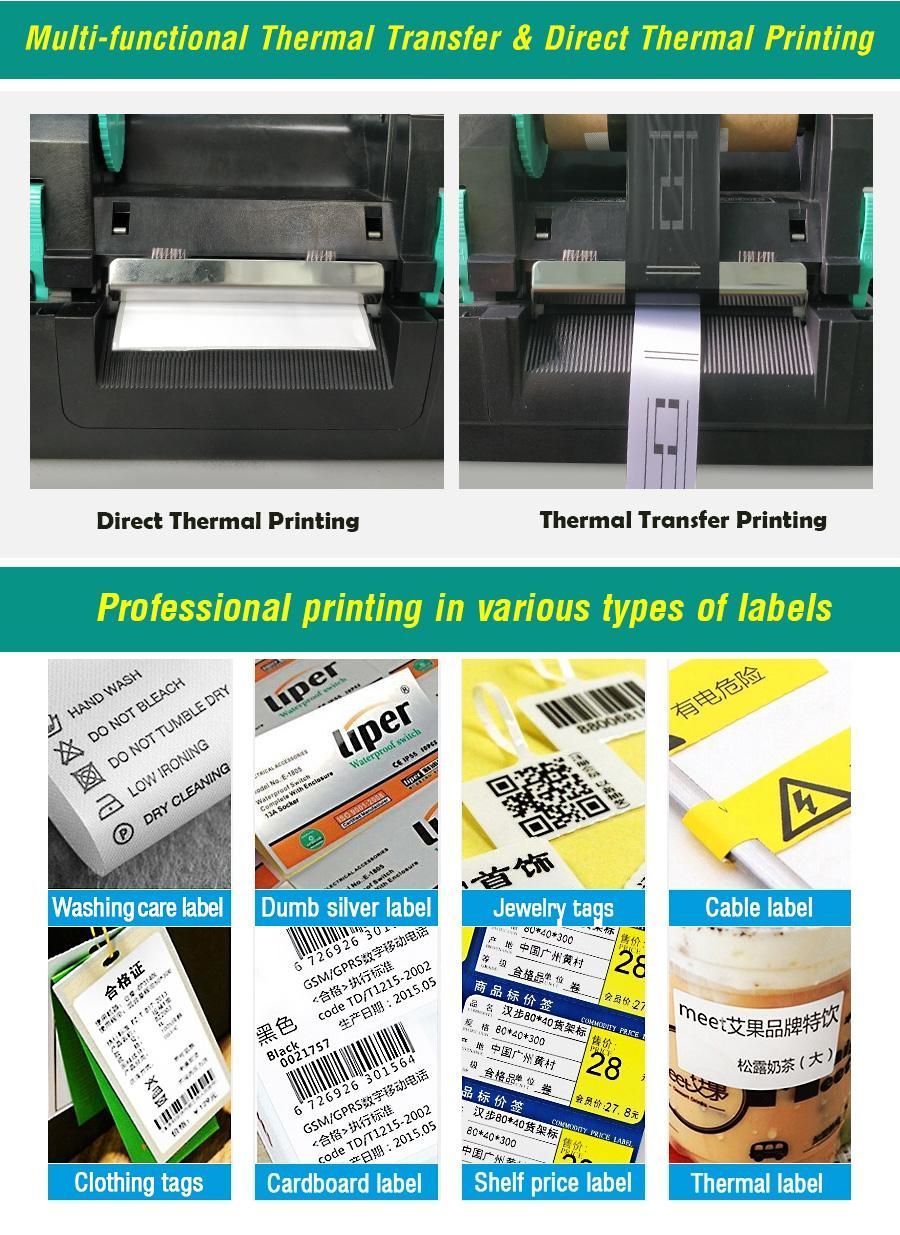

A barcode printer is a specialized printer. The biggest difference between barcode printers and ordinary printers is that the printing of barcode printers is based on heat, and the printing is completed with carbon ribbon as the printing medium (or directly using thermal paper). The biggest advantage of this printing method compared with ordinary printing methods is that Continuous high-speed printing can be achieved unattended.

The content printed by the barcode printer is generally the company’s brand logo, serial number logo, packaging logo, barcode logo, envelope label, clothing tag, etc.

The most important part of the barcode printer is the print head, which is composed of a thermistor. The printing process is the process of the thermistor heating to transfer the toner on the ribbon to the paper. Therefore, when purchasing a barcode printer, the print head is a component worthy of special attention, and its cooperation with the carbon ribbon is the soul of the entire printing process.

In addition to the printing functions of ordinary printers, it also has the following advantages:

1.Industrial-grade quality, not limited by the amount of printing, can be printed 24 hours;

2.Not limited by printing materials, it can print PET, coated paper, thermal paper self-adhesive labels, polyester, PVC and other synthetic materials and washed label fabrics;

3.The text and graphics printed by thermal transfer printing have anti-scratch effect, and the special carbon ribbon printing can also make the printed product have the characteristics of waterproof, anti-fouling, anti-corrosion and high temperature resistance;

4.The printing speed is extremely fast, the fastest can reach 10 inches (24 cm) per second;

5.It can print continuous serial numbers and connect to the database to print in batches;

6.The label paper is generally several hundred meters long, which can reach thousands to tens of thousands of small labels; the label printer adopts the continuous printing method, which is easier to save and organize;

7.Not restricted by the working environment;

In order to ensure the quality and long-term good performance of the barcode printer, it needs to be cleaned regularly.

01

Cleaning of the print head

To clean the print head regularly and regularly, the cleaning tools can be cotton swabs and alcohol. Turn off the power of the barcode printer, keep the same direction when wiping (to avoid dirt residue when wiping back and forth), turn the print head up, and remove the ribbon , label paper, use a cotton swab (or cotton cloth) soaked in print head cleaning solution, and gently wipe the print head until it is clean. Then use a clean cotton swab to gently dry the printhead.

Keeping the print head clean can get good printing results, and the most important thing is to prolong the life of the print head.

02

Cleaning and Maintenance of Platen Roller

It is necessary to regularly clean the bar code printer glue stick. The cleaning tool can use cotton swabs and alcohol to keep the glue stick clean. It is also to obtain a good printing effect and prolong the life of the print head. During the printing process, the label paper will remain on the glue stick. A lot of small powder, if it is not cleaned in time, it will damage the print head; the glue stick has been used for a long time, if there is wear or some unevenness, it will affect the printing and damage the print head.

03

Cleaning of the rollers

After cleaning the print head, clean the rollers with a cotton swab (or cotton cloth) soaked in 75% alcohol. The method is to rotate the drum by hand while scrubbing, and then dry it after it is clean. The cleaning interval of the above two steps is generally once every three days. If the barcode printer is used frequently, it is best to once a day.

04

Cleaning of the drive train and cleaning of the enclosure

Because the general label paper is self-adhesive, the adhesive is easy to stick to the shaft and channel of the transmission, and dust will directly affect the printing effect, so it needs to be cleaned frequently. Generally once a week, the method is to use a cotton swab (or cotton cloth) soaked in alcohol to wipe the surface of each shaft of the transmission, the surface of the channel and the dust in the chassis, and then dry it after cleaning.

05

Cleaning of the sensor

Keep the sensor clean so that paper errors or ribbon errors do not occur. The sensor includes a ribbon sensor and a label sensor. The location of the sensor is shown in the instructions. Generally, it is cleaned once every three months to six months. The method is to wipe the sensor head with a cotton swab soaked in alcohol, and then dry it after cleaning.

06

Paper guide cleaning

There is generally no major problem with the guide groove, but sometimes the label sticks to the guide groove due to man-made or label quality problems, it is also necessary to clean it in time.

Post time: Aug-11-2022